When entering the electronics manufacturing industry or reconsidering how to manage your manufacturing needs, understanding the variations in specific manufacturing roles and terminology will allow you to make an educated choice when selecting a manufacturing partner.

The growing demand for consumer electronics and innovative technological advancements allows manufacturers to capitalise on current opportunities. With rising customer demands and the need to control costs, manufacturers may need to partner with solution providers that offer industry expertise and experience.

As a global leader in high-mix, low-volume manufacturing, we see the industry's evolution and understand the critical role we play. This article offers a handy guide to electronics manufacturing terminology and the different parts manufacturers, and providers play.

As noted, manufacturing solutions vary depending on the need.

The expectation is that the industry's revenue growth will be around US $725 billion by 2027, at a compound annual growth rate (CAGR) of 7.5%.

Collaborations and other strategic initiatives are becoming increasingly prevalent among OEMs, EMS providers, CEMs, ODMs, and stakeholders as they work to adapt to the fast transitions in the manufacturing space.

First, let's clarify these unique terms and the roles they play in the electronics value chain.

Manufacturing Models: Differences and Similarities

[OEMs, CEMs, ODMs, and EMS Providers]

Starting with the definition...

1. OEMs - Original Equipment Manufacturers

OEM originally referred to a company that manufactured material to be sold to and used by other companies. Other companies would purchase the equipment produced by an OEM to create their product. OEMs usually don't play a direct role in determining the finished product.

However, there is a second, newer definition of OEM, typically used in electronics industries. In this case, OEM may refer to the company that buys products or outsources their manufacture and then incorporates or rebrands them into a new product (source)

2. CEM - Contract Electronics Manufacturers

CEMs are companies that make products under contract for other companies.

Contract manufacturers provide, design, and create different products used by OEMs in other more sizable products. The OEMs will brand the product with their name for sale to its customer base.

3. ODM - Original Design Manufacturers

ODMs typically specialise in a small number of specific product types.

Similar to CEMs, ODMs can design and manufacture a product. ODM manufacturing allows you to use a supplier to produce whatever good you can make only minor changes to the existing product.

This model is mainly used in international trade. A local ODM is used to produce goods for a foreign company that sees some advantage in the transaction, such as low labor inputs, transport links, or markets' proximity. (source)

ODM manufacturing is limited because you purchase a pre-designed and pre-produced product that will then go on to be rebranded and sold as your own. It's beneficial to smaller companies as they do not have to waste time on R&D (Research & Development).

4. EMS - commonly referred to as Electronics Manufacturing Services

The core of any electronics manufacturing service offering stems from design, manufacture, test, and distribution. An EMS provider will perform these functions, including full systems assembly for original equipment manufacturers.

For example, offering systems integration or "box build" services - manufacturers can use a process to combine printed circuit board assemblies, wire harnesses, fabrication of enclosures, testing, and more.

EMS companies offer a wide array of value-added services, including design, testing solutions, global supply chain management, fulfilment, and more.

The term "electronics manufacturing services” (EMS) refers to the overall industry and also to a specific class of subcontractor or company.

EMS companies provide a wide range of value-added engineering and manufacturing outsourcing services to original equipment manufacturers (OEMs), allowing them to improve operational efficiencies and focus on core activities like research and development (R&D).

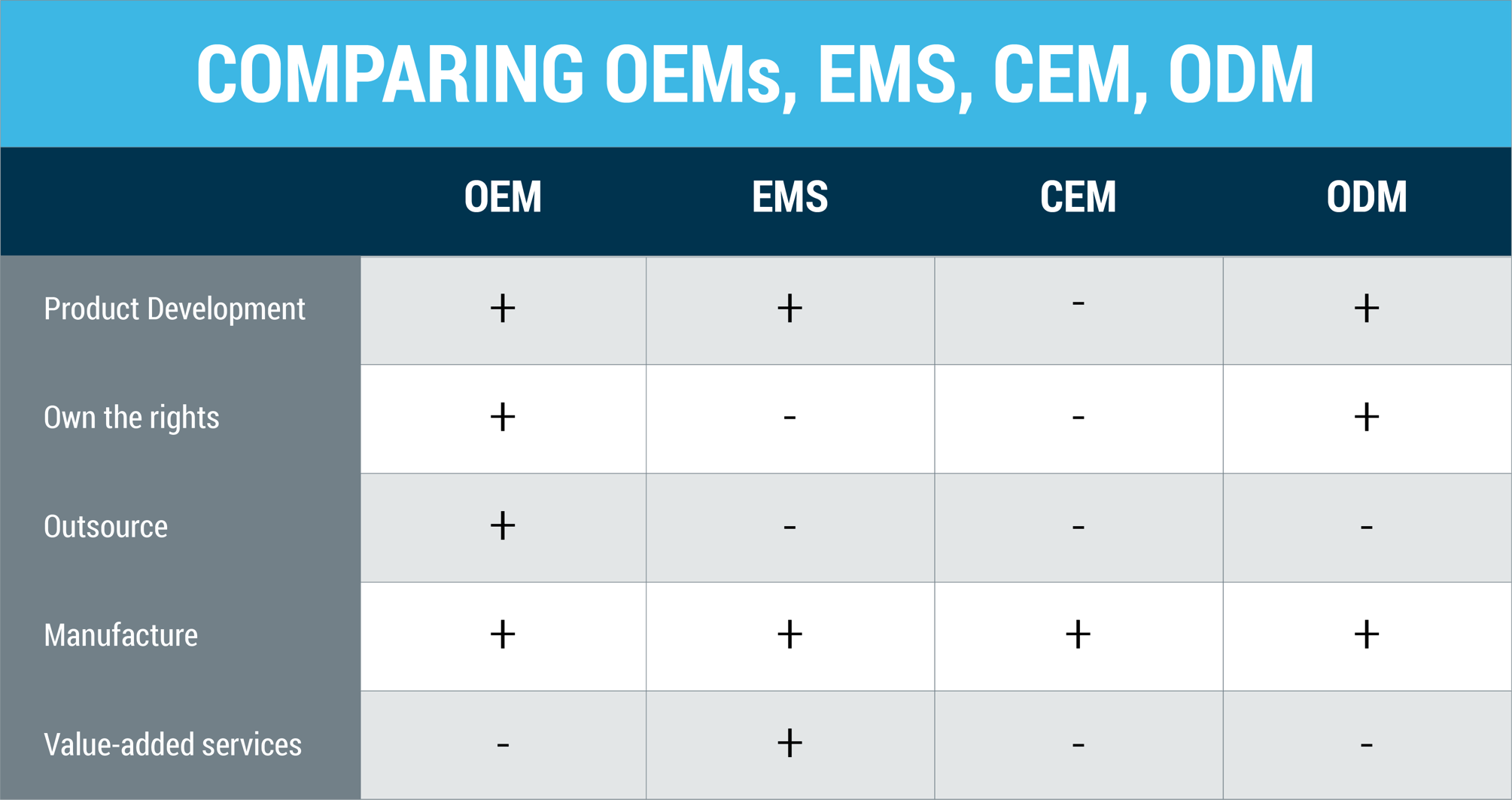

Comparison by Role OEMs, EMS, CEM, ODM

Engineers, supply chain managers, quality managers, sales teams, and everyone else involved in the EMS industry might raise a question...

What/Who is the best manufacturing solution for my new product?

The correct answer is always whichever best suits your needs. Only 56 percent of new products meet all of the NPI success criteria. Common reasons for failure include a lack of product design and development, and various manufacturing models can be used to address this problem.

The chart below demonstrates and compares the roles different manufacturing models contribute to production.

Electronics Manufacturing Acronyms to Know: From an Electronics Manufacturing Partner Perspective

We thought we would gather a few of the commonly used acronyms in the industry. Some are used interchangeably.

AVL - Approved Vendor List

An approved vendor list (AVL) is a compiled list of all the vendors or suppliers (also referred to as an “Approved Supplier List” or “ASL”) approved by a company as sources from which to purchase parts or materials.

BOM - Bill of Materials

A bill of materials (BOM) is a comprehensive list of parts, items, assemblies, and other materials required to create a product, as well as instructions required for gathering and using the materials needed.

CAD - Computer-aided design

Computer-aided design (CAD) uses computers (or workstations) to aid in the creation, modification, analysis, or optimisation of a design.

CCA – Circuit Card Assembly

A Circuit Card Assembly (commonly referred to as a CCA) is a flat board with connected electronic components placed on it. CCA Manufacturing usually employs the use of machines (SMT and Through-hole) to automate the process of creating CCAs.

CEM - Contract electronics manufacturers

Contract manufacturers provide, design, and create different products used by OEMs in other more sizable products. The OEMs will brand the product with their name for sale to its customer base.

CM - Contract manufacturing

A contract manufacturer is a manufacturer that contracts with a firm for components or products. It is a form of outsourcing.

DFx - Design for Excellence

Design for Excellence (or Design for X, or DfX) is a set of services to analyse how your product has been designed.

DFm – Design for Manufacturing

Design for manufacturing is the general engineering practice of designing products in such a way that they are easy to manufacture. The concept exists in almost all engineering disciplines, but the implementation differs widely depending on the manufacturing technology.

EMS - Electronics Manufacturing Services

Electronics manufacturing services will give you a streamlined process and save you time and money, resulting in a smoother, more effortless path to market.

EOL - End of Life

An electronic item is considered end-of-life (EOL) once it becomes non-functional and beyond economic repair. Once the technology becomes so outdated, the item is no longer eligible for reselling.

ESS - Environmental Stress Screening

Environmental stress screening refers to the process of exposing a newly manufactured or repaired product or component to stresses such as thermal cycling and vibration in order to force latent defects to manifest themselves by permanent or catastrophic failure during the screening process.

HALT/HASS - Highly Accelerated Life Test/ Highly Accelerated Stress Screen

HALT & HASS are unique, accelerated product reliability testing methods focused on finding defects in products so they can be fixed before becoming expensive field issues.

HLA – High-Level Assembly

High-Level Assembly Manufacturing (HLA) is an operations process that utilises key in-house assembly solutions to simplify production, manage floor space, reduce inventory and achieve budgeting goals.

HMI – Human Machine Interface

In the industrial design field of human-computer interaction, a user interface is a space where interactions between humans and machines occur.

IC – Integrated Circuit

An integrated circuit or monolithic integrated circuit is a set of electronic circuits on one small flat piece of semiconductor material, usually silicon.

MCM – Multi-Chip Module

A multi-chip module is generically an electronic assembly where multiple integrated circuits, semiconductor dies, and/or other discrete components are integrated, usually onto a unifying substrate. In use, it can be treated as if it were a larger IC.

NFSSD - Non-Franchised Supplier Document

Non-Franchised Source means any source that is not authorised by the OEM or OCM to sell its product lines. Non- franchised sources may also be referred to as brokers or independent distributors.

NPI - New product introduction

New Product Introduction (NPI) is the process of establishing a clear plan to take your product from concept to its final form.

ODM - Original design manufacturers

An original design manufacturer is a company that designs and manufactures a product, as specified, that is eventually rebranded by another firm for sale.

OEM - Original equipment manufacturers

An original equipment manufacturer is generally perceived as a company that produces parts and equipment another manufacturer may market.

PCB - Printed circuit board

A printed circuit board mechanically supports and electrically connects electronic components using conductive tracks, pads, and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate.

PCBA - Printed circuit board assemblies

Printed circuit board assembly is the process of connecting the electronic components with the wirings of printed circuit boards.

PIL - Production-linked incentive

A production-linked incentive offers a simple and direct incentive based on incremental sales, designed to boost domestic manufacturing and attract significant investments in mobile phone and specified electronic component manufacturing units.

PLC – Product Life Cycle

Product life-cycle management is the succession of strategies by business management as a product goes through its life-cycle.

PoP – Package on Package

A PoP is a chip package that contains two ball grid array (BGA) chips. A package on package (PoP) typically includes a RAM chip on top and a CPU chip on the bottom.

RFID- Radio Frequency Identification

Radio-frequency identification uses electromagnetic fields to automatically identify and track tags attached to objects.

SCM - Supply chain management

Supply chain management, the management of the flow of goods and services between businesses and locations, includes the movement and storage of raw materials, work-in-process inventory, and finished goods, and end-to-end order fulfillment from the point of origin to point of consumption.

SMT - Surface-mount Technology

Surface-mount technology is a method that electronic components are assembled with automated machines that place components on a printed circuit board's surface.

Outsourcing Manufacturing: What You Need to Know

What is Outsourcing Manufacturing?

Outsource manufacturing consists of an OEM contracting another company to assemble or build part or all of their product. Contract Electronics Manufacturers (CEMs) are examples of outsourcing manufacturing, as they build or assemble products under contract to be used by other companies.

When Does Outsourcing Manufacturing Make Sense?

Companies mainly choose to outsource to cut costs. A company's highest cost is often labor, followed by overhead, focus, and demand.

Identifying and Qualifying the Right Provider

Selecting the right EMS provider can be overwhelming. The EMS partner you choose should tailor their services to meet your needs. They should see your vision and be willing to work side by side. To help you find the right fit, we have created a list of questions to help you identify and qualify the right provider for you.

Bonus Content: Get a copy of The Questions You Need to Ask Your EMS Provider as a PDF that you can easily access anytime.

Additional resources:

The Beginner's Guide to Outsource Manufacturing

A Comprehensive Guide to Smart Outsourced Manufacturing

Conclusion

The surging demand for electronics and technologies creates growth opportunities in many electronics-related industries. The electronics manufacturing service (EMS) market is dynamic, and the need for electronic components and outsourced manufacturing services grows along with increased demand.

With rising customer demands and the need to control costs, manufacturers may need to partner with solution providers that offer industry expertise and experience.

At TT Electronics, we're typically a good fit for people looking for:

- A way to scale production quickly that can't do it in-house

- Reliable, collaborative Electronics Manufacturing Partner, not a "one-off project"

- A provider who works as an extension of your team

- Supply chain optimisation

- An EMS company that supports High-Mix, Low-Volume needs in some of the most demanding markets

TT Electronics has developed a global business process founded on the support of complex high-mix, low-volume devices. We are inspired to help solve global electronics manufacturing challenges from design through fulfilment for customers requiring support for high-reliability products in high-mix, low-volume markets.